|

Product name |

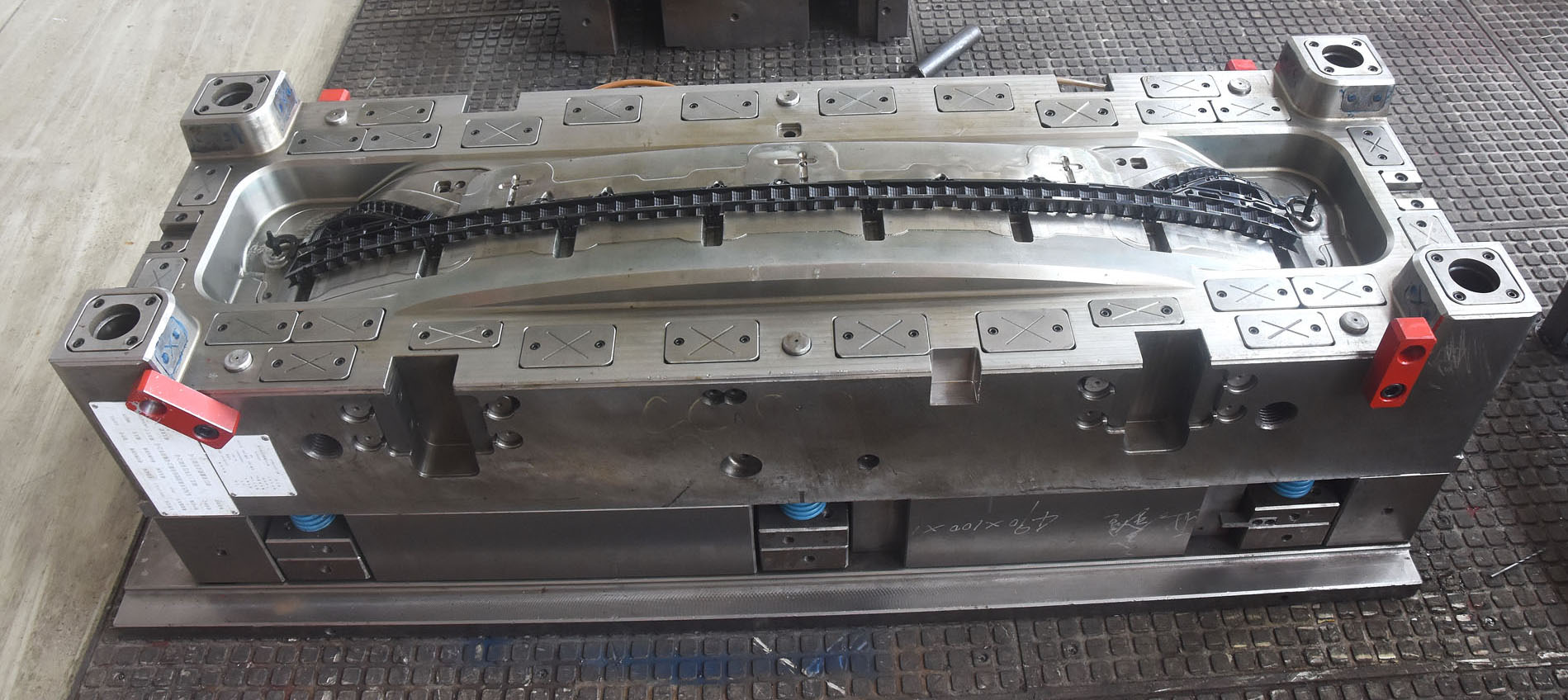

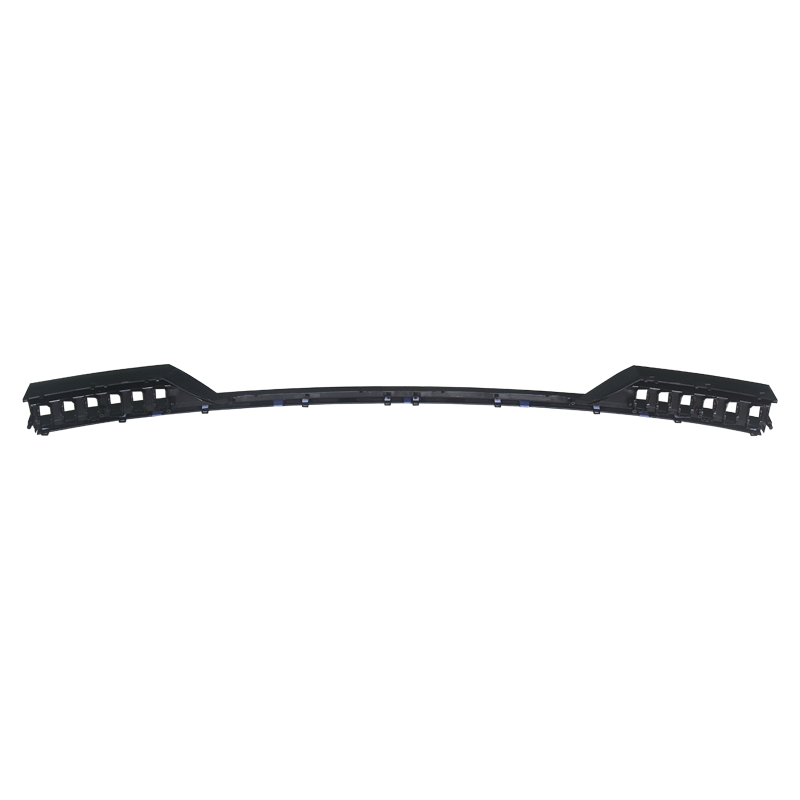

Popular OEM new energy Automotive long tail lamp mould |

|

Product Material |

ABS+PC |

|

Mould cavity |

L+R/1+1 etc |

|

Mould life |

500,000 times |

|

Mould testing |

All of the moulds can be well tested before the shipments |

|

Shaping Mode |

Plastic Injection Mould |

Each mold will be packed in sea-worthy wooden box before delivery.

1) Lubricate mold with grease;

2) Enroll the mold with plastic film ;

3) Pack in a wooden case.

Usually molds will be shipped by sea. If in very urgent need, molds can be shipped by air.

Lead Time: 70 days after receipt the deposit

Q1: Whether to accept customized?

A1: Yes.

Q2: Where is your factory located? How can we visit there?

A2: Our factory is located in Tai Zhou City, Zhe Jiang Province, China. From Shanghai to our city, it takes 3.5hrs by train, 45mins by air.

Q3: How about the package?

A3: Standard export wooden case.

Q4: How long is the delivery time?

A4: Under normal conditions, products are delivered within 45 working days.

Q5: How can I know the status of my order?

A5: We will send you photos and videos of your order at different stage in time and keep you informed of the latest information.

Long Tail Lamp Mould - Revolutionizing Automotive Lighting Design.

In the automotive industry, lighting plays a significant role in vehicular safety and aesthetics. Our Long Tail Lamp Mould is the perfect solution for your automotive lighting production needs. As a highly experienced and professional manufacturer of automotive light moulds, we take pride in presenting the most innovative and reliable product on the market.

Our Long Tail Lamp Mould is a cutting-edge precision mould designed to produce top-quality automotive lights specifically tail lamps. The mould material is of high-grade quality and meets international automotive standards, ensuring that our client receives exceptional quality products from our production process. Our production technology ensures a flexible and customizable mould, which is adaptable for different types of vehicles and tail lamps.

Our Long Tail Lamp Mould is versatile and can be used for the manufacture of automotive tail lamps for a wide variety of vehicles. Passenger cars, commercial vehicles, SUVs, trucks, and buses are just a few examples. Our high-quality mould can be adapted to suit a variety of specifications, allowing for customised production.

1. Experience and Professionalism - Our team of experienced professionals has decades of experience in the design and development of vehicle-based moulds.

2. High-Quality Moulds - Our Long Tail Lamp Mould is engineered using cutting-edge technology, ensuring that customer satisfaction is paramount. Our precision mould can produce consistent high-quality automotive lighting pieces.

3. Cost Effective - Our innovative and customized mould designs offer high-quality production processes at an affordable price. Our mould's modular design allows for the reduction of production costs without sacrificing quality.

1. Precision Production - Our Long Tail Lamp Mould is capable of producing exceptionally precise vehicle lighting designs, ensuring that every production cycle creates top-quality products that meet international automotive standards.

2. Customizable - Our moulds are tailored to match our customer's specific requirements. By providing a modular and customizable mould design, we offer a personalized service that creates a unique experience for our customers.

3. Durability - Our Long Tail Lamp Mould is built to last, made from high-quality materials to withstand the rigours of automotive production.

Our Long Tail Lamp Mould is an essential product for anyone in the automotive lighting manufacturing business.

As a highly experienced and professional manufacturer of automotive light moulds, we are committed to providing our customers with the highest quality products possible. Our modular and customizable mould design is engineered using cutting-edge technology, making our product affordable, durable, and highly efficient.

Contact us today to learn more about how our Long Tail Lamp Mould can help revolutionize your automotive light production process.