| Product name | Plastic Car Side Mirror Cover Mould |

| Product Material | PP,PC,PS,PA6,POM,PE,PU,PVC,ABS,PMMA etc |

| Mould cavity | L+R/1+1 etc |

| Mould life | 500,000 times |

| Mould testing | All of the moulds can be well tested before the shipments |

| Shaping Mode | Plastic Injection Mould |

Each mold will be packed in sea-worthy wooden box before delivery.

1) Lubricate mold with grease;

2) Enroll the mold with plastic film ;

3) Pack in a wooden case.

Usually molds will be shipped by sea. If in very urgent need, molds can be shipped by air.

Lead Time :30 days after receipt the deposit

Our goal is to make quality your top priority and bring leading automotive parts to every country.

1. All products should be inspected before handling.

2. Time and quality control. We are manufacturers, have our own factories, and the factories produce their own products.

3. We have a dedicated team that will serve our customers wholeheartedly.

The position of the vehicle seat and steering wheel must be adjusted before adjusting the mirrors. The basic principle of adjusting the seat is to sit comfortably, have a clear view and use the steering wheel. Maintaining the correct sitting posture is the premise of adjusting the rearview mirror, and the rearview mirror adjusted when the sitting posture is not correct can not play its proper role.

Q1: What is the delivery time of your product? (How long do you need to prepare my goods?)

A1: Volume production orders take 30 to 45 days (based on different quantities).

Q2: How will you ship the goods to me?

A2: We are generally shipping.

Q3: How long do I have to wait to get to my merchandise?

A3: Sea transportation is 20-40 days

Q4: How is the quality of your product?

A4: We have a strong quality control team to guarantee the quality of our standards.

Q5:How much precision can the mold do?

A5:We can guarantee an accuracy of 0.01mm.

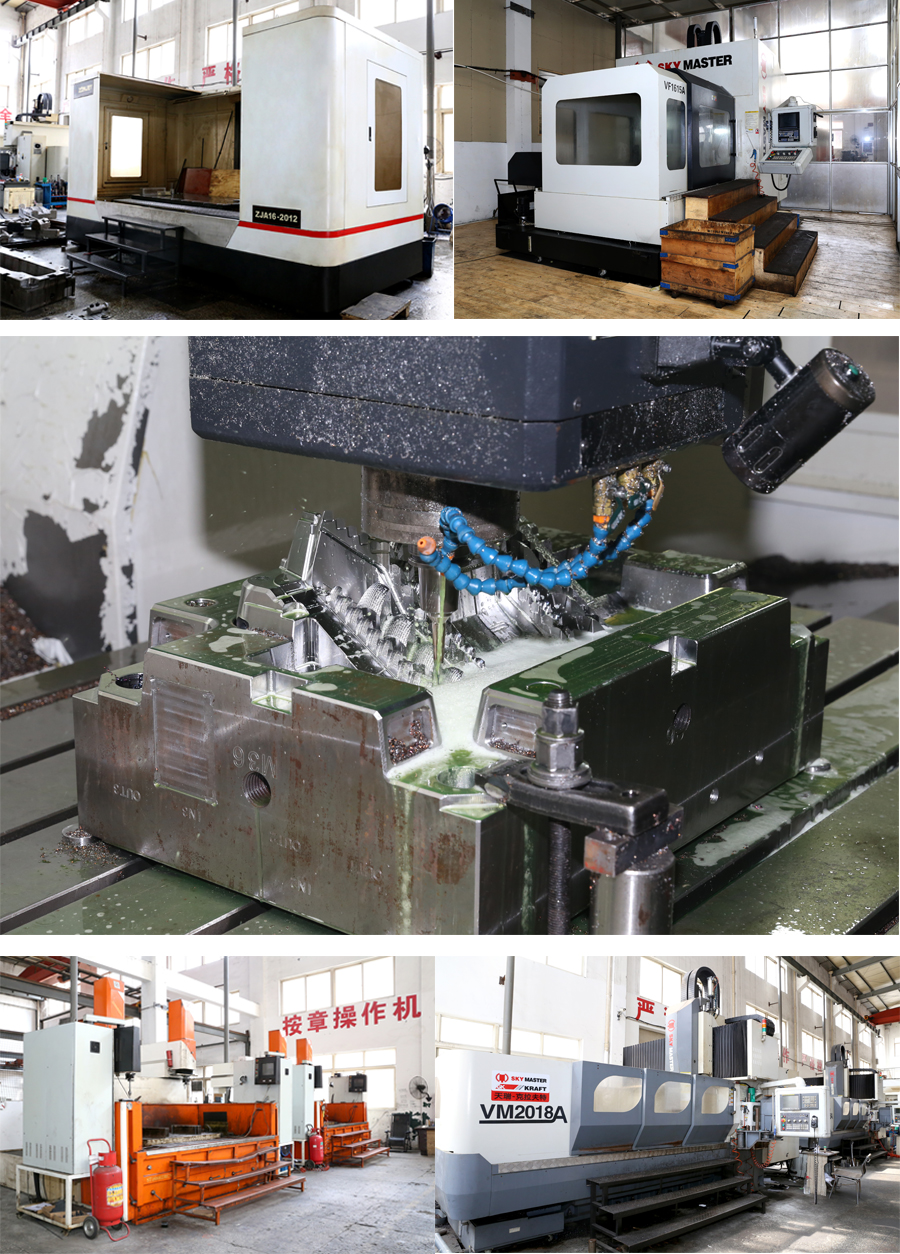

Zhejiang Yaxin Mould Co., Ltd. was established in 2004 and is located in Huangyan, Taizhou, Zhejiang Province. We specialize in the design and manufacture of automotive parts molds, children's molds, household appliance molds, household molds and commodity molds. The company has grown into an excellent mold manufacturer with a strong engineering team.

Customer satisfaction is our greatest motivation. Welcome friends from all walks of life come to visit, guide and negotiate business.