1. The processing enterprise should first equip each pair of molds with a resume card, detailing and counting its use, care (lubrication, cleaning, rust prevention) and damage, according to which components and components can be damaged and the degree of wear and tear is Provide information and materials for discovering and solving problems, as well as molding process parameters of the mold and materials used in the product, so as to shorten the test time of the mold and improve production efficiency.

2. The processing enterprise should test the various properties of the mold under the normal operation of the injection molding machine and the mold, and measure the size of the final molded plastic part. Through this information, the existing state of the mold can be determined, and the cavity and core can be found. The damage of the cooling system and the parting surface, etc., according to the information provided by the plastic parts, the damage state of the mold and the maintenance measures can be judged.

3. It is necessary to carry out key tracking and inspection on several important parts of the mold: the function of the ejection and guiding parts is to ensure the opening and closing movement of the mold and the ejection of the plastic parts. If any part is stuck due to damage, it will lead to production stoppage. Always keep the mold thimble and guide column lubricated (to choose the most suitable lubricant), and regularly check whether the thimble, guide post, etc. are deformed and surface damage, once found, should be replaced in time; after completing a production cycle, the mold must be The working surface, movement and guiding parts are coated with professional anti-rust oil, especially the protection of the elastic strength of the bearing parts with gears, rack and die and spring molds to ensure that they are always in the best working condition; The time is continuous, the cooling channel is easy to deposit scale, rust, sludge and algae, which makes the cross section of the cooling channel smaller, the cooling channel narrows, greatly reduces the heat exchange rate between the coolant and the mold, and increases the production cost of the enterprise.

“The cleaning of the flow channel should be taken seriously.” Luo Baihui, a hot runner mold expert, said that the maintenance of the heating and control system is beneficial to prevent production failures, so it is especially important. Therefore, after each production cycle, the belt heater, rod heater, heating probe and thermocouple on the mold should be measured with an ohmmeter. If it is damaged, it should be replaced in time and with the mold history. Compare and make records so that problems can be discovered at the right time and countermeasures can be taken.

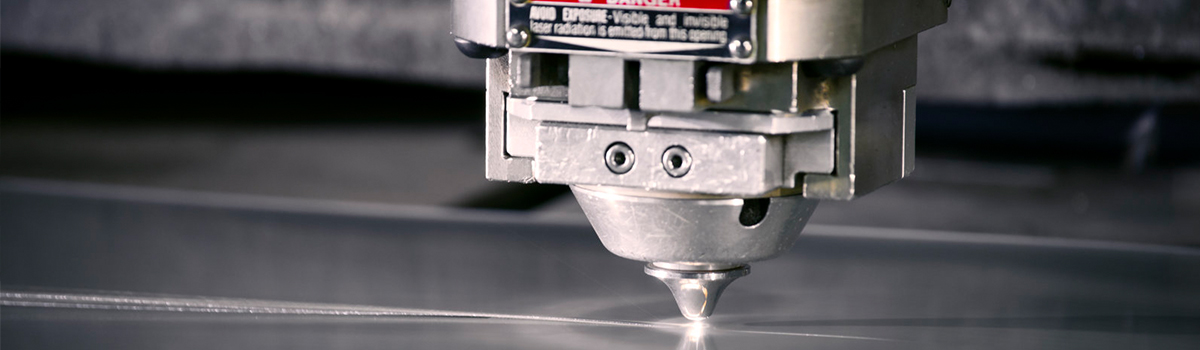

4, should pay attention to the surface maintenance of the mold, it directly affects the surface quality of the product, the focus is to prevent corrosion. Luo Baihui believes that it is especially important to choose a suitable, high-quality, professional anti-rust oil. After the mold has completed the production task, the residual injection molding should be carefully removed according to different injection molding methods. The residual injection molding and other deposits in the mold can be removed by using copper rods, copper wires and professional mold cleaning agents, and then air-dried. Disable the cleaning of hard objects such as wire and steel bars to avoid scratching the surface. If there is rust caused by corrosive injection molding, use a grinder to grind and polish, spray professional anti-rust oil, and then store the mold in a dry, cool, dust-free place. A typical molding structure is as shown.

Post time: Apr-23-2023