-

Manufacturing Experience

Over 15 years' experience in automotive mould making, since our founding in 2004, Yaxin Mould is always on developing the highest quality injection moulds.more -

30% average Annual sales growth

World-class automotive mould manufacture meeting European and American standards.more -

Over 30 countries and regions

Worldwide market covering. We supply quality goods and services to over 30 countries and regions, including China automotive factories, US, India, Russia, S. America, etcmore

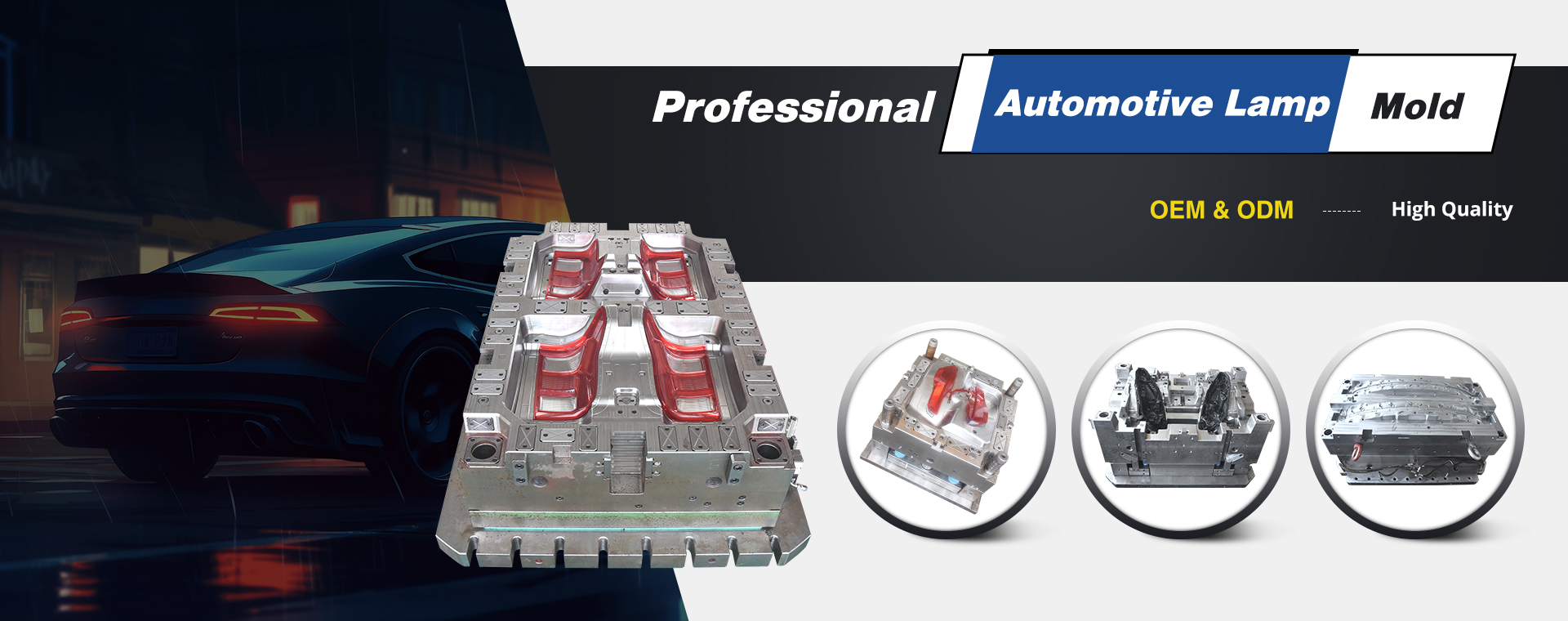

Zhejiang Yaxin Mould Co., Ltd. is located in Huangyan Taizhou Zhejiang Province, the hometown of Mold. It enjoys convenient transportation and is a gathering place for industrial and commercial trade. The company was founded in 2004 and focuses on its own automotive parts mold innovation and development. After several years of hard work, it gradually became a professional modern enterprise of OEM Automotive parts molds,specially in Lamp molds ,Bumper molds, exterior and interior parts for cars.

-

High-Quality Auto Bumper Injection Mould for Pr...

-

High toughness and high strength automobile fen...

-

Precision Automotive Interior Moulds for Perfec...

-

High-Quality Radiator Plastic Tanks Moulds for ...

-

Upgrade Your Car Decor with Our Premium Quality...

-

Plastic Car Side Mirror Cover Mould

-

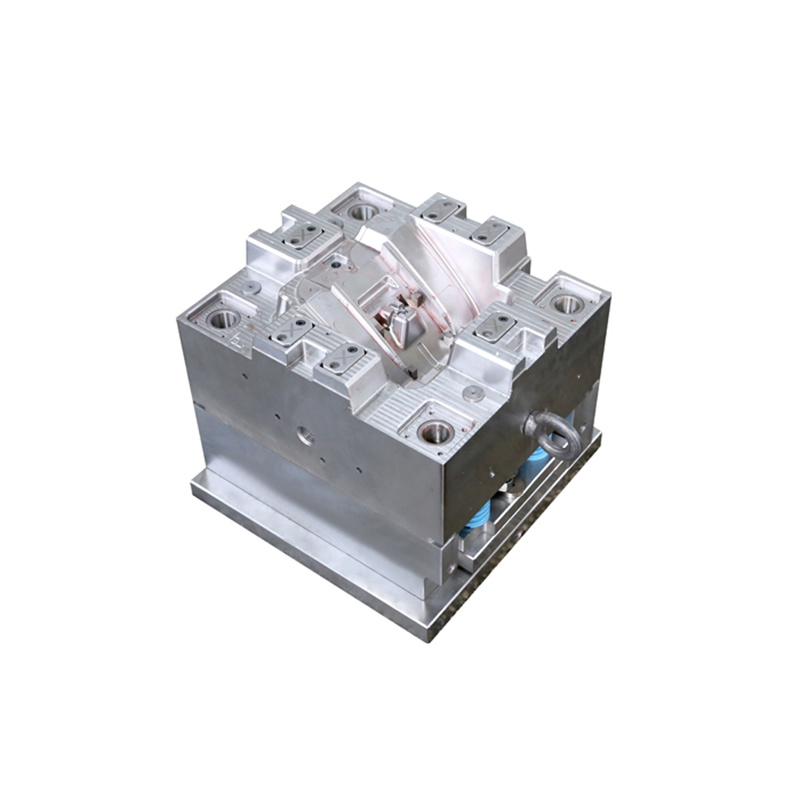

Precise and Durable Auto Reflector Mould for Yo...

-

Custom-auto-lamp-mould for High-quality, Effici...

-

Automotive Headlight Molding: Key Process...25-04-01Meta Description: Explore advanced injection molding techniques for automotive headlight molds. Learn about material selection, precision design, and sustainability trends in car lamp manufacturing. Introduction The automotive lighting industry demands extreme precision, with headlight molds requiring tolerance levels under 0.02mm. As vehicle designs evolve toward slimmer LED arrays and adaptive driving beams, injection mold engineers face unprecedented challenges. This guide breaks down ...

-

MAXIMIZING EFFICIENCY AND COST SAVINGS WI...25-01-09In today’s fast-paced business world, staying ahead of the competition is crucial. One way to do this is by maximizing efficiency and cost savings. Injection molding rapid prototyping is an effective method for achieving these goals. By utilizing this technique, businesses can save time and money while still producing high-quality prototypes. In this blog post, we will explore the benefits of injection molding rapid prototyping and how it can help businesses maximize...

-

DEVELOPMENT TREND OF AUTOMOTIVE INJECTION...24-09-11Over the past 30 years, the application of plastics in automotive has been increasing. The consumption of automotive plastics in developed countries accounts for 8%~10% of the total consumption of plastics. From the material used in modern automobiles, plastic can be seen everywhere, whether it is exterior decoration, interior decoration, or functional and structural parts. The main components of the interior decoration are dashboard, door inner panel, auxiliary dashboard, sundry box cover, s...